Rules for laying vinyl laminate. Tools, coating options, installation details and installation steps. How to lay vinyl laminate flooring Glue vinyl laminate flooring

Vinyl laminate installation- a convenient solution for those who want to get a beautiful, durable and durable floor. The material consists of several layers: the top is protective, contains aluminum oxide and protects the pattern from fading.

Laminate accurately imitates different types of coatings - wood, bamboo, marble. They produce a particularly durable quartz vinyl laminate with the addition of porcelain stoneware chips and antibacterial components.

The material has many advantages: it is flexible, non-brittle, resistant to stress. You can safely move furniture or walk in heels on the floor - no traces will remain. Vinyl laminate does not require special care. Serves for a long time - more than 25 years.

According to the type of fastening, vinyl laminate can be self-adhesive and lockable. Self-adhesive is mounted on an adhesive smart tape or on a special ready-made adhesive solution. The lock is connected with a Click lock. Both methods are simple and do not take much time.

How to prepare your floor for laying vinyl laminate

Any surface is suitable for laying vinyl laminate: concrete, linoleum, wood, old laminate, tile.

The surface must be hard, even, dry, smooth and clean. Check with a level or rule to see if there are elevation changes. Permissible irregularities - up to 1 mm per 3 m. Strong differences will have to be leveled with a screed or plywood. Seal the cracks with a cement mixture: this also applies to tile joints if the floor is tiled. Degrease and vacuum the coating.

Vinyl laminate is also mounted on a warm floor, only 3 days before the start of work, the system must be turned off. And after installation, do not turn it on for another week.

The process of laying vinyl laminate

Take your time to unpack your new laminate: keep it indoors for 48 hours to get used to the temperature and humidity.

A few words about the substrate. Under self-adhesive vinyl laminate, it is not required. If the type of connection is lock, then the substrate is needed.

- Installation of vinyl laminate takes place at a temperature in the room from 17 to 25 degrees. Humidity should not exceed 5%.

- Boards are laid indented from the wall. The size of the indent is at least 5 mm.

- The smart tape is cut at the side of the panel that will face the wall. The panels are laid with a “ladder” - offset by a third. This makes the overall pattern of the coating neat and natural.

- After gluing, each board needs to be walked with a roller for a stronger grip on the floor.

- If the type of fastening is a lock, they are mounted in the same way, with a shift of one third.

- Holes are cut out under the pipes in the laminate.

Upon completion of the installation, the skirting boards are installed. Paul is ready!

vinyl laminate flooring cost

In our company you can order turnkey installation of vinyl laminate: we will prepare a rough coating, and then we will quickly and professionally mount the laminate. At your choice, we will do any type of styling.

The cost of laying vinyl lock laminate on prepared is 345 r / m². If you want to lay the laminate diagonally or in a herringbone pattern, then the cost of the work will increase to 450 r / m².

Laying vinyl laminate is a new flooring variation that has become popular recently. The relatively short period of use is not the only reason why there are no negative reviews about this material. The cost of such a coating is higher, but the service life is several times greater than many other alternative options.

It's no secret that today many people prefer natural floor materials, which is why they buy ordinary wooden parquet. Yes, it is characterized by absolute environmental friendliness, a high level of safety, as well as an attractive appearance. But, few people know that parquet also has a number of negative characteristics. Natural wood is often subjected to various mechanical damage. Scratches on it are a common thing, to say nothing of the fact that the cost is simply prohibitive.

Yes, of course, you can say that if you hire specialists to lay a laminate, the price can also be sky-high. But why spend money when you can mount everything yourself?

There are many of them, but the most important were recognized:

- wear resistance;

- strength;

- water resistance;

- environmental friendliness;

- ease of installation;

- availability;

- aesthetics.

Unlike other alternative coatings, this one is characterized by beauty and sophistication. It is quite durable and wear-resistant to the appearance of dents from furniture and household appliances, scratches, abrasion and shock. Vinyl flooring does not crumble or crack even under heavy loads.

Since the water resistance is very high, the material can be laid safely even in the bathroom and other rooms with a high level of humidity. A considerable advantage is that the material is made from environmentally friendly components, which means that it does not contain any harmful chemicals.

So, you can always save money, effort and time by choosing a vinyl laminate installation.

Design for every taste

Everyone and everyone is well aware of the proverb "The taste and color ...". Indeed, sometimes it is difficult to find what is right for your interior. When choosing a vinyl coating, you do not have to worry about such trifles. The modern market offers a variety of decorative ornaments and colors: from more restrained to bright and very original. So, the flooring can look like ceramic tiles, marble or natural wood. Thanks to the imitation of natural materials, you can purchase high-quality flooring in accordance with the style of the interior.

Types of vinyl laminate

Today, there are several popular types of this material, and we are not talking about a possible imitation of natural stone, wood, tile, marble, etc., but about functional indicators.

Experts distinguish the following variations:

- Self-adhesive material. It is used in cases where more traditional floors are not suitable (basements, bathrooms, baths and other rooms). Self-adhesive material perfectly retains heat and is wear-resistant. It can be easily mounted over linoleum, ceramics and even plywood.

- Contesse slabs are one of the most popular options, with unique properties such as resistance to excessive moisture, as well as to chemicals and disinfectants.

- Super waterproof or the so-called quartz vinyl laminate containing vinyl of special strength and finely crushed porcelain stoneware. Technology often used in production Nano Silver, which combines nanotechnology and the usefulness of silver. Therefore, this type is used in hospitals, hospitals and maternity hospitals. In addition, they can finish not only the floors, but also the walls of the premises.

What should be the basis for the installation of such material? Completely different coatings can serve as the basis. The main unifying qualities are rigidity, integrity and strength. There are a lot of options:

- Wooden floors, chipboard, plywood and linoleum bases. In this case, the base must be even, strong, dry and clean.

- Screed. If there are any cracks or potholes, it is better to fill them with cement or quality putty.

- Tiles (stone or ceramic). The base should not be embossed. Noticeable irregularities and seams between the plates can be filled with putty or cementing mixture.

- Lightweight concrete. As in the previous version, the cracks are filled with a cementing mixture or putty.

- Linoleum. The material must be well attached to the base and not have obvious damage.

How to lay laminate?

For installation you will need the following tools:

- roulette;

- stationery knife;

- pencil;

- square;

- ruler.

In principle, it is similar to laying a conventional laminate flooring. Start the slab installation from the corner of the room, cutting the first slab if necessary. Each next one must be laid end-to-end on the adhesive surface, and then pressed well. If there is a need to cut holes for pipes, use metal shears.

Are you going to lay the material on an imperfectly even base? Use a hair dryer. As unusual as it may sound, it is the hot air that will help make the plates more flexible, which is necessary for a quality installation. The advantage is that even if you made some mistake during installation, and the defect is noticeable, you can install the plate again.

After the flooring elements are laid, walk over them with a special roller. So, the joints will be firmly glued, and the corners will not lag behind. Installation of such a floor is a fairly easy task, taking only a couple of hours. Remember that a properly prepared surface will ensure a long blade life.

If you regularly and efficiently care for the coating, you will be able to enjoy its beauty for a long time. For proper care, it is better to purchase special brushes. Don't forget to wet and dry clean the floor as well. So, vinyl laminate will last longer.

If you want to learn more about how to handle the installation, check out the photos of laying laminate flooring. They will help you figure out how and where to get started. Trust me, anyone can do it. Follow the above instructions and tips. Make your home more comfortable! Good luck!

Video, installation of vinyl laminate.

Vinyl laminate is one of the most modern flooring options. This material has many advantages. One of the main positive qualities of this material is that the laying of vinyl laminate can be done by hand in the shortest possible time. The coating is somewhat more expensive than the closest analogues, but its service life is much longer.

What you need to know before installing vinyl laminate flooring

Before you decide to install such a laminate, you need to know that this common name combines several different types of materials. The main component is the same - they are all made of vinyl, but the performance can vary significantly. It can be a flexible laminate with smart tape and adhesive backing, vinyl flooring with locks and tiles. The laying technology of each of them has its own characteristics. However, having dealt with the general features of laying, you will cope with the installation of any coating.

Before laying the laminate, it must be allowed to rest. Bringing coated boxes into the house, do not rush to unpack them immediately. This is done so that the laminate adapts to the surrounding conditions. If the material was transported at an air temperature below +10 degrees, then the box can be opened no earlier than after 2 days. If it was warmer outside, it will be enough to wait 1 day.

In order for the self-laying of the laminate to be as quick, easier and better as possible, it is necessary that the air temperature in the room does not fall below +15 and does not rise above +26 degrees for 24 hours before the start of finishing work and the same amount of time after their completion.

Laying the laminate should be carried out at a humidity not higher than 60%.

In the event that the laminate is mounted on a heated floor, the system must be turned off 3-4 days before laying and not turned on for at least 6 days after its completion.

To install vinyl laminate flooring, you will need the following tools:

- stationery knife;

- ruler;

- pencil;

- roulette;

- square.

Surface Preparation Guide

Before laying laminate flooring, the surface must be cleaned and allowed to dry. This requirement is true for any type of coverage. It is especially important to observe it if the laminate will be glued directly to the base, i.e. if non-floating laying is performed.

Substrate moisture content should not exceed 5%. Vinyl laminate does not allow moisture to pass through, so if it is in excess, it will simply collect under the coating and gradually destroy the adhesive composition. After a while, the finish will fall off.

A hygrometer is used to measure surface moisture. If you do not have such a device, you can use the following method: take a piece of plastic film 100x100 cm, lay it on the surface and fix it around the perimeter with adhesive tape. Leave for 24 hours. If condensation collects on the inner surface of the film, the humidity of the base exceeds the permissible limits.

The procedure for leveling the surface varies depending on which coating will be laid. So, if it is planned to lay tiles that are glued to the base, the surface must be carefully leveled. Otherwise, all defects will be imprinted on the laminate. Many manufacturers attach great importance to leveling the floor and recommend using special self-leveling compounds for this.

Laminate, laid on the so-called. floating technology, does not stick to the surface, so you can not pay much attention to alignment. It will be enough just to close up deep cracks with putty. For example, a flexible vinyl laminate with adhesive locks can even be laid on a surface with differences of up to 3 mm per 1 m². Some varieties of such a coating can even be laid on the old finish, without the need for its preliminary dismantling.

Surface preparation is completed by cleaning of debris, it must be dedusted. If dust gets on the adhesive lock or mixture, this will reduce the adhesion of the laminate to the base. The surface must be thoroughly swept and vacuumed, and then primed.

Step by step instructions for laying laminate flooring

The technology of laying a vinyl laminate in the event that panels with locks are being installed does not provide for the creation of markings. Such materials belong to the express methods of fast flooring, so there is nothing superfluous in the process of laying them. Laying such a laminate starts from the wall farthest from the entrance opening. The first tiles are fixed in the corner. The entire surface is gradually filled towards the exit.

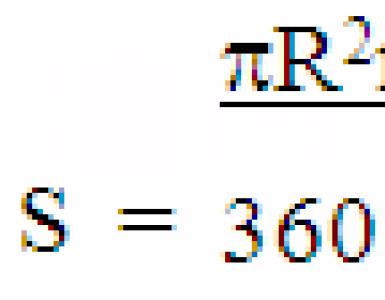

The coating, which uses glue, is laid on a pre-marked surface. First you need to find the center of the base, the field of which, relative to the center, divides the surface into 4 equal sections. Laying tiles or planks begins within the area that is the furthest away from the entrance. The first tiles are laid out from the previously established center of the room.

Take a notched trowel and apply dispersion or acrylic adhesive to the surface. Wait until it dries a little and start laying the laminate. Work is carried out in the direction away from you, i.e. you will need to move forward on the already mounted cover. Fill the entire surface and check the quality of the installation. Pay special attention to corners and edges. They must be necessarily even, otherwise you can not count on the durability of the coating - the elements will disappear. It is better to correct such defects immediately.

Excess glue must be removed from the coating with a clean cloth dipped in soapy water. Floors can be washed at least 24 hours after laying is completed. Furniture and other interior items can be brought into the room no earlier than after 2 days. During this time, the adhesive that you used when laying the laminate will dry completely and gain the desired strength. Covering with smart-tape or adhesive-based does not require such precautions. Furniture can be brought in immediately after finishing work is completed.

It is important not only to install the laminate correctly, but also to monitor and properly care for it after installation. Stains from various kinds of food should be removed immediately with a special liquid cleaner for such surfaces. It is not recommended to use dishwashing detergents, soap, various household powders, etc. The best option is a biodegradable cleaner. It does not need to be washed off with water and leaves no residue. The same tool should be used to remove any stains. When using a liquid cleaner, follow the manufacturer's instructions.

Stubborn soiling and stubborn stains can be removed by polishing the flooring. First you need to thoroughly sweep or vacuum the flooring to remove any dirt and loose particles. In this case, it is not recommended to mix polishes and cleansers, because. this will reduce the cleaning quality.

Be sure to find out what products your laminate manufacturer recommends for cleaning. There is a decorative coating with a non-porous and dense surface. This ensures that the coating is protected from dirt and wear. Do not use wax to clean this laminate. It will not penetrate into the structure of the material, which will lead to an even more intensive accumulation of contaminants. If it is used intensively enough and its appearance has deteriorated, you can use a special cleaner and polish for vinyl coating. Such a decorative laminate is very easy to maintain, but in order for it to look good during the entire period of operation, it is necessary to periodically apply polish to it.

If you notice deep scratches on the coating, it is better to replace the damaged elements immediately. Less deep scratches (these usually appear during simple home use) can be tried with a vinyl matte finish. Apply it in 1-2 layers.

If you are unable to resolve the problem yourself, please consult with your flooring manufacturer. Successful work!

This coating has recently appeared on the market of building finishing materials and immediately attracted attention. On the one hand, this was expected. Flooring manufacturers are aware that only a material with better characteristics than laminate can compete with the super popular classic laminate, while the new material must be just as easy to install and maintain. On the other hand, consumers have long formed an idea of the cheapness and unpretentiousness of PVC tiles, and it was not easy to “break” this stereotype.

What is vinyl laminate?

It looks like classic laminate panels. The panel may consist of a layer of compressed vinyl, reinforcing mesh, quartz sand, a decorative layer with a photo-printed pattern and a protective layer of polyurethane varnish with the addition of aluminum oxide. Such a floor covering has 43 wear resistance classes and a thickness of about 4 mm.

Different manufacturers offer vinyl laminate, made using different technologies. The panel can be composed of a substrate, HDF-board, vinyl layer, decorative and protective layers. In this case, the thickness of the panel reaches 10 mm.

According to the method of fastening, self-adhesive and locking coatings are distinguished. The self-adhesive laminate has a special adhesive film protruding beyond the dimensions of the panel (smart tape). The second type has a click connection, and its laying is not much different from laying a laminate with a similar lock.

Benefits of the new material

The main advantages of vinyl laminate are due to its composition:

- It has exceptional wear resistance, manufacturers give a guarantee for 10-25 years of operation.

- It has great strength, is practically not subject to mechanical damage, it cannot be scratched. On the vinyl laminate there are no traces of furniture, women's heels, animal claws.

- It has good moisture resistance and is approved for installation in bathrooms.

- Possesses resistance to chemical influences.

- Possesses fire resistance.

- The undoubted advantages include a huge selection of colors, patterns and textures.

- Approved for use in children's and medical institutions. To say that vinyl laminate is the same environmentally friendly material as wood or ceramics, apparently, is not worth it. But vinyl (PVC, polyvinyl chloride) is inert in this state. It does not even accumulate electric charges.

- It has good sound and heat insulation properties. It feels like a "warm" material.

- It is easy to install and does not require special care in the future.

A relative disadvantage is its higher cost compared to other floor coverings. This is partly offset by a very long service life of the material.

Substrate surface requirements

The surface of the base must be solid, free of defects and damage and have rigidity. As an example, there are different types of base and how they are prepared before laying:

- Cement-sand floor screed. All cracks and potholes are sealed with a cementing mixture, the surface is leveled.

- Plywood, wooden floor, linoleum, chipboard. The surface must be clean, dry, even, solid (strong). Linoleum must be firmly attached to the floor. Serious defects are not allowed.

- Ceramic or stone tiles should not have a relief surface. Seams between tiles and surface defects are filled with a cementing mixture or putty.

The height difference should not exceed 2 mm for every 2 meters. A uniform slope of 4 mm is allowed on a surface area of 2 meters.

All types of surfaces require thorough cleaning before installation. Dust and dirt will interfere with the quality installation of vinyl laminate, especially with a self-adhesive edge.

Vinyl laminate installation

Packages with the material are brought into the room where the laying will take place, and are there for 2 days to adapt to temperature and humidity. The room temperature must be at least 15°C. Open packages immediately before installation.

Important! Floor heating is switched off simultaneously with the storage of material in the room. It is recommended to turn on the heating 7 days after the installation is completed.

For laying a self-adhesive coating, it is necessary to prepare:

Before laying, the panels are removed from the packages and laid out on the floor so that they take their original shape and straighten out.

At the first panel, 1/3 of the length should be cut off for laying with an offset of a third of the board. So the floor will look neat. To maintain the distance between the walls in the room and the flooring around the perimeter of the room, plastic stops are installed along the walls. After installation, they are removed.

Important! No underlayment is required for laying self-adhesive vinyl laminate on a flat surface. Under the material with a locking connection, the substrate is laid.

On the side of the panel that will be facing the wall, the adhesive tape is cut off. The first row is laid, the second one starts from the trimmed part of the panel. The panel should be brought to the laid tiles at an angle, and carefully glued to the protruding smart tape. After the row is laid, roll the joints of the panels with a special roller. Subject to the rules of laying, a smooth, solid surface is obtained.

If the panel is light with an offset (uneven), within 10 minutes it is possible to remove and replace it, while the smart tape cannot be damaged.

For laying in places with a complex configuration, it is better to use a template.

One of these coatings is a vinyl laminate, it appeared relatively recently, but quickly gained fame and popularity.

Producers praise this material and if you listen only to them, it turns out that it has only positive qualities. To understand this, let's take a closer look at what PVC laminate is, what advantages does it have, does it have disadvantages?

Vinyl laminate is a floor covering made from polyvinyl chloride., you can purchase this material in the form of tiles, panels or in rolls. If we talk about the parameters of the panels, then they usually have dimensions of 191x1316, 324x655 mm, and tiles with dimensions of 300x150, 300x300, 200x200, 490x490 mm.

The peculiarity of this flooring is its small thickness usually it does not exceed 5 mm. This allows you to lay the vinyl laminate on a solid old base, and the height of the room from this decreases slightly.

The specified floor covering consists of the following layers:

- adhesive layer, if there are locking joints, then it may be absent;

- a heat-insulating substrate is also not available in all models of such a coating;

- polyvinyl chloride base;

- fiberglass serves to ensure the flexibility of the coating and protect it from tearing;

- fiber optic layer;

- the printed image allows you to create different shades and structures;

- a layer of transparent PVC protects the material from damage;

- polyurethane layer;

- treatment with ultraviolet rays increases the light resistance of the coating.

Advantages and disadvantages

Due to the presence of a large number of advantages, vinyl laminate flooring successfully competes with many traditional coatings. Among its advantages it is worth noting the following:

- the presence of a large selection of colors and patterns, which allows you to imitate any materials;

- ease of cleaning and maintenance;

- vinyl laminate is waterproof, so it can be used in the bathroom, kitchen or similar areas;

- it is comfortable to walk on it, it is warm and soft;

- low cost;

- high strength;

- good maintainability;

- ease of installation.

- the presence of chemicals in it can cause irritation of the mucous membranes and respiratory diseases, this usually happens at the first time, after the installation of such a coating;

- this material is not biodegradable, therefore, after the end of its service life, it litters the environment;

- non-renewable natural resources are used for the production of vinyl laminate;

- the surface of the subfloor must be flat and free of debris, as the presence of solid particles leads to damage to the vinyl coating;

- marks from heels or rubber mats can cause a chemical reaction that results in discoloration of the material;

- there is no way to restore such a floor; in case of damage, it is replaced;

- over time, a poor quality coating may turn yellow;

- releases toxic fumes when burned.

Kinds

There is a classification of this material according to the purpose of its use:

- household pvc laminate for flooring in rooms with low traffic, designed for covering, for example, in bedrooms or living rooms;

- commercial purpose, has a thicker coating layer, so it can be used in rooms with medium and high attendance;

- special coating used for laying in gyms, shopping centers, as it can withstand heavy loads and has high wear resistance.

The most popular and famous is Contesse vinyl laminate, which is a worthy competitor to traditional floor materials. It can be used both in apartments or houses, as well as in schools, shops, offices.

The bottom layer of such a coating consists of wear-resistant polyvinyl chloride, and the top layer is reinforced with fiberglass and covered with a protective layer of polyurethane and aluminum oxide. This structure makes Contesse vinyl laminate durable, its service life is about 10-15 years, and in residential areas it can last 25-30 years.

In addition, flooring can be divided into several types:

self-adhesive

It can be made both in the form of panels and in the form of tiles of various sizes; a layer of glue is applied on its back side, which is protected by a film. It is convenient to mount it yourself, the only condition is that the surface is flat and clean.

Castle

In this case, the vinyl laminate is made with a lock joint and adhesive tape, the panels are connected using locks, they are not attached to the floor, and adhesive tape is used to seal the joints. This type is great for underfloor heating systems.

In this case, the vinyl laminate is made with a lock joint and adhesive tape, the panels are connected using locks, they are not attached to the floor, and adhesive tape is used to seal the joints. This type is great for underfloor heating systems.

roll material

This type of vinyl laminate is the most difficult to lay, due to the need to use a special adhesive, which has a high cost. It is made in the form of strips rolled into a roll.

This type of vinyl laminate is the most difficult to lay, due to the need to use a special adhesive, which has a high cost. It is made in the form of strips rolled into a roll.

Quartz vinyl laminate

The peculiarity is that it has a three-layer structure. Between the protective bottom layer and the top layer, which is responsible for the appearance of the coating, there is an intermediate layer consisting of quartz chips. Such a structure makes this material very durable, and it belongs to class 43, but the cost of this coating will be high.

Mounting process

Before laying a vinyl laminate, it is necessary to prepare the surface with high quality, the base can be of different types:

- cement-sand screed;

- plywood or chipboard;

- installation can be carried out on the old coating, but at the same time the linoleum under the laminate must be firmly attached to the base, the tile must not have a relief, and the seams must be filled with putty.

Before installation, it is necessary to carefully clean the entire surface from debris and dust. The material must lie in the room for 2 days to adapt to its conditions. The room temperature should not be less than 15°C.

The first panel is cut off by 1/3 to get an offset, wedges are installed around the perimeter of the room, which are removed after laying the laminate.

When laying a self-adhesive vinyl laminate, no underlay is used, if it is with a locking joint, then the underlay must be laid.

On the panel located from the wall, the adhesive tape is cut off, after which the second panel is brought and carefully glued. After laying the row, the joints of the panels must be well rolled with a special roller.

If the element is uneven or misaligned, you can correct or replace it within 10 minutes, but do not damage the smart tape.

If the vinyl laminate has a lock connection, then it is laid on the substrate, its strips are connected to each other with adhesive tape, and then the panels with the Click lock are installed, as usual.

For laying rolled material, it is necessary to use a special glue, the cost of which is high and installation is quite difficult, so beginners should not choose the specified laying method.

Which is better, laminate or pvc tiles?

It is impossible to answer unambiguously the question of which is better, ordinary or PVC, it all depends on the desire of the owner and the conditions in which the flooring will be used.

If we talk about PVC laminate, then its advantage over the usual one will be in a small thickness, so the height of the room decreases slightly, it is great for laying on underfloor heating and can be used in rooms with high humidity.

In both cases, it is necessary to properly prepare the surface so that it is even, and there is no dust and dirt on it. Please note that PVC laminate can cause allergies, especially immediately after installation, so it is not advisable to use it in the children's room.

Is an underlay needed?

If self-adhesive vinyl laminate is being laid, no underlayment is required. In the case of using a cover with interlocks, you can use an underlay that will help hide small bumps and act as additional cushioning. The underlay for vinyl laminate can be either cork or coniferous, or polypropylene or a combination.

If self-adhesive vinyl laminate is being laid, no underlayment is required. In the case of using a cover with interlocks, you can use an underlay that will help hide small bumps and act as additional cushioning. The underlay for vinyl laminate can be either cork or coniferous, or polypropylene or a combination.

Which glue to choose

For laying vinyl laminate, you must use a special adhesive that will provide a strong and durable connection.

- Water-dispersion adhesive is odorless, safe for humans and provides a reliable connection.

- Click Guard glue is a cross between an adhesive and a sealant, so the panels are not only securely fastened, but also protected from moisture.

- Glue Moment is used to connect the ends of the panels, it dries very quickly and allows you to connect the planks butt-to-butt.

Worst glue ever experts believe that it is created on the basis of artificial resins and has acetone in its composition.

The best option It is considered a universal adhesive for laminate.

Summarizing

Vinyl laminate flooring requires a near-perfectly level base, so you'll have to work hard at it. It is best to level the floor with a self-levelling screed or plywood sheets. It is not recommended to level OSB sheets under self-adhesive material, because due to the roughness of the base, the connection may not be very strong.

Useful video

Step-by-step instructions for laying vinyl laminate with your own hands

In contact with