Design, advantages and disadvantages of incandescent lamps. Evaluation of design elements and technical characteristics of incandescent lamps. Glow of filament in an incandescent lamp.

It's no secret that even now, with the advent of many new energy-saving light sources, the incandescent lamp (also called the “Ilyich lamp” or tungsten lamp) remains in great demand, and many are not yet ready to give it up. Most likely, a little more time will pass and this lighting device will practically disappear from the electrical equipment market, but, naturally, it will not be forgotten. Indeed, in fact, with the discovery of the ordinary incandescent lamp, a new era in lighting began.

What is a tungsten light bulb made of?

The design of an incandescent lamp with a tungsten filament is very simple. It consists of:

- flask, i.e. the glass sphere itself, either evacuated or filled with gas;

- filament bodies (incandescent filament) – spirals made of tungsten alloy;

- two electrodes through which voltage is applied to the spiral;

- hooks – tungsten filament holders made of molybdenum;

- light bulb legs;

- external link of the current lead, serving as a fuse;

- plinth housings;

- glass base insulator;

- contact bottom of the base.

The operating principle of an incandescent lamp is also simple. Light is produced because the tungsten filament heats up from the voltage applied to it. A similar glow, albeit in smaller volumes, can be seen when operating an electric stove with an open nichrome heating element. The light emitted from the spiral is very weak, but this example makes it clear how an incandescent lamp works.

In addition to the usual form, these lighting devices can also be decorative, in the form of a candle, drop, cylinder or ball. Since light from tungsten is always the same color, manufacturers produce such lighting devices with different, sometimes colored glasses.

Light bulbs with incandescent filaments with a mirror coating are interesting to work with. The principle of operation of an incandescent lamp can be compared with spotlights, since they illuminate a specific area in a directional manner.

Advantages

Of course, the main advantages of incandescent lamps are the minimal complexity in their manufacture. Hence, naturally, the low price, because today it is impossible to imagine a simpler electrical device. The same story applies to the inclusion of such an element in the network. To do this, you do not need to install any additional equipment; a simple cartridge is enough.

In some cases, even in its absence, people connect incandescent lamps by hastily constructing a socket from wood, plastic, or even connecting the lamp to the wire using insulating tape. Of course, such connections have a right to exist in force majeure circumstances, but they are unsafe in terms of fire and electrical protection (it is necessary to ensure that the base does not heat up).

Also, light bulbs with high power filaments (150 W) are very widely used in lighting greenhouses. Indeed, in addition to the fact that they provide light, as a result of the incandescence of the tungsten filament, the lamps become very hot. In addition, the lighting from them is closest to sunlight; a modern LED light bulb or energy-saving fluorescent light bulb cannot boast of this. For the same reason, an incandescent lamp has an advantage in terms of its effect on human vision.

Flaws

The disadvantages of incandescent lamps include the fragility of operation of such devices; this directly depends on such a parameter as the network voltage. If you increase the current, the spiral will begin to wear out faster, which will lead to burnout in the thinnest place. Well, if you lower the voltage, the lighting will become much weaker, although, of course, this will increase the life of the lamp.

The main disadvantages of incandescent lamps also include the negative effect of sharp voltage surges on the filament. But this drawback can be eliminated by installing an input stabilizer. Of course, the question remains with turning on the lighting. After all, at the moment the voltage is applied, the filament is cold, which means its resistance is lower. This problem is solved by installing a simple rotary dimmer. Then, as you turn the handle, the thread will heat up more smoothly (i.e., there will be no short, sharp supply of voltage), which means it will last much longer.

But still, the main disadvantage of these devices, of course, can be considered their low efficiency, namely, the fact that a working lamp spends the vast majority of energy on heat, as a result of which it begins to heat up very much. These losses amount to up to 95%, but this is the operating algorithm of tungsten lamps. So when purchasing this lighting device, you should take into account all the advantages and disadvantages of an incandescent lamp.

Types of incandescent lamps

Light bulbs using tungsten filament can be not only vacuum. The incandescent lamp design distinguishes several types of similar lighting devices, each of which is used in certain industries. They can be:

- vacuum, i.e. the simplest;

- argon or nitrogen-argon;

- krypton, which shine 13–15% stronger than argon;

- xenon (more often used recently in car headlights and shining 2 times brighter than argon);

- halogen - the bulb in an incandescent lamp is filled with bromine or iodine halogen. The light is 3 times brighter than argon, but these lamps do not tolerate voltage drops and external contamination of the bulb glass;

- halogen with a double bulb - with increased efficiency of halogens in saving tungsten in the filament;

- xenon-halogen (even brighter) - in addition to the halogens iodine or bromine, they are also filled with xenon, since what kind of gas is in the flask directly determines how many degrees the lamp heats up and, therefore, its brightness also depends .

Efficiency

As already mentioned, due to the fact that the structure of an incandescent lamp involves heating the coil, 95% of the energy supplied to the lighting device goes into heat generated during its operation, and only 5% goes directly to lighting. This heat is infrared radiation, which human eyes cannot perceive. Therefore, the efficiency of such lighting devices when the temperature of the incandescent lamp increases to 3,400 K will be 15%. When it is reduced to 2,700 K (which corresponds to a lamp operating temperature of 60 Watts), the efficiency of the lamps will be 5%. It turns out that with increasing temperature conditions, the efficiency also increases, but at the same time the service life decreases significantly. This means that if the current decreases, the efficiency also decreases, but the durability of the device will increase thousands of times. This method of increasing the service life of lamps is often used in the entrances of apartment buildings, where power sources are supplied in series to two lighting fixtures, or a diode is connected in series to the lamp, which allows the network current to be reduced.

What to choose: LEDs or tungsten lamps?

This is a question that everyone finds the answer to for themselves, evaluating incandescent lamps, their advantages and disadvantages. There can be no advice here. On the one hand, LEDs consume many times less electricity and are more durable in operation, which cannot be said about “Ilyich bulbs”, and on the other hand, incandescent lamps have a more gentle effect on human vision.

And yet there are statistics, and according to it, sales of LEDs and energy-saving lamps have recently increased by more than 90%, because it is human nature to keep up with progress, which means that the time is not far when incandescent lamps will become a thing of the past.

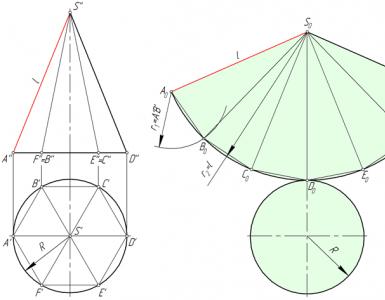

Analyzing the structure of an incandescent lamp (Figure 1, A) we find that the main part of its structure is the filament body 3 , which heats up under the influence of electric current until optical radiation appears. The principle of operation of the lamp is actually based on this. The filament body is fastened inside the lamp using electrodes 6 , usually holding its ends. Through the electrodes, electric current is also supplied to the filament body, that is, they are also internal links of the terminals. If the stability of the filament body is insufficient, additional holders are used 4 . The holders are mounted on a glass rod by soldering 5 , called a staff, which has a thickening at the end. The post is associated with a complex glass part – the leg. The leg, it is shown in Figure 1, b, consists of electrodes 6 , plates 9 , and shtengel 10 , which is a hollow tube through which air is pumped out of the lamp bulb. General connection between intermediate terminals 8 , staff, plates and rods form a blade 7 . The connection is made by melting the glass parts, during which an exhaust hole is made 14 connecting the internal cavity of the evacuation tube with the internal cavity of the lamp bulb. To supply electric current to the filament through electrodes 6 use intermediate 8 and external conclusions 11 , connected to each other by electric welding.

Figure 1. The structure of an electric incandescent lamp ( A) and her legs ( b)

A glass bulb is used to isolate the filament body, as well as other parts of the light bulb from the external environment. 1 . The air from the internal cavity of the flask is pumped out, and an inert gas or a mixture of gases is pumped in instead 2 , after which the end of the rod is heated and sealed.

To supply electric current to the lamp and secure it in the electric socket, the lamp is equipped with a base 13 , which is attached to the neck of the flask 1 carried out using capping mastic. The lamp leads are soldered to the appropriate places on the base. 12 .

The light distribution of the lamp depends on how the filament body is located and what shape it is. But this only applies to lamps with transparent bulbs. If we imagine that the filament is an equally bright cylinder and project the light emanating from it onto a plane perpendicular to the largest surface of the luminous filament or spiral, then the maximum luminous intensity will appear on it. Therefore, to create the necessary directions of light intensities, in various lamp designs, the filaments are given a certain shape. Examples of filament shapes are shown in Figure 2. Straight non-spiral filament is almost never used in modern incandescent lamps. This is due to the fact that with an increase in the diameter of the filament body, heat loss through the gas filling the lamp decreases.

Figure 2. Design of the filament body:

A- high-voltage projection lamp; b- low-voltage projection lamp; V- ensuring obtaining an equally bright disk

A large number of filament bodies are divided into two groups. The first group includes filament bodies used in general-purpose lamps, the design of which was originally conceived as a radiation source with a uniform distribution of luminous intensity. The purpose of designing such lamps is to obtain maximum luminous efficiency, which is achieved by reducing the number of holders through which the filament is cooled. The second group includes the so-called flat filament bodies, which are made either in the form of parallel spirals (in powerful high-voltage lamps) or in the form of flat spirals (in low-power low-voltage lamps). The first design is made with a large number of molybdenum holders, which are attached with special ceramic bridges. A long filament is placed in the form of a basket, thereby achieving high overall brightness. In incandescent lamps intended for optical systems, the filament bodies must be compact. To do this, the filament body is rolled into a bow, double or triple spiral. Figure 3 shows the luminous intensity curves created by filament bodies of various designs.

Figure 3. Luminous intensity curves of incandescent lamps with different filament bodies:

A- in a plane perpendicular to the axis of the lamp; b- in a plane passing through the axis of the lamp; 1

- annular spiral; 2

- straight coil; 3

- a spiral located on the surface of the cylinder

The required luminous intensity curves of incandescent lamps can be obtained by using special bulbs with reflective or diffusing coatings. The use of reflective coatings on an appropriately shaped bulb allows for a significant variety of luminous intensity curves. Lamps with reflective coatings are called mirror lamps (Figure 4). If it is necessary to ensure particularly precise light distribution in mirror lamps, bulbs made by pressing are used. Such lamps are called headlight lamps. Some incandescent lamp designs have metal reflectors built into the bulbs.

Figure 4. Mirror incandescent lamps

Materials used in incandescent lamps

Metals

The main element of incandescent lamps is the filament body. To make a filament body, it is most advisable to use metals and other materials with electronic conductivity. In this case, by passing an electric current, the body will heat up to the required temperature. The material of the filament body must satisfy a number of requirements: have a high melting point, plasticity that allows drawing wire of various diameters, including very small ones, a low evaporation rate at operating temperatures, which ensures a long service life, and the like. Table 1 shows the melting temperatures of refractory metals. The most refractory metal is tungsten, which, along with high ductility and low evaporation rate, has ensured its widespread use as the filament of incandescent lamps.

Table 1

Melting point of metals and their compounds

| Metals | T, °С | Carbides and their mixtures | T, °С | Nitrides | T, °С | Borides | T, °С |

| Tungsten Rhenium Tantalum Osmium Molybdenum Niobium Iridium Zirconium Platinum | 3410 3180 3014 3050 2620 2470 2410 1825 1769 | 4TaC+ +HiC 4TaC+ +ZrC HfC TaC ZrC NbC TiC W.C. W2C MoC VnC ScC SiC | 3927 3887 | TaC+ + TaN HfN TiC+ + TiN TaN ZrN TiN BN | 3373 3087 | HfB ZrB W.B. | 3067 2987 2927 |

The evaporation rate of tungsten at temperatures of 2870 and 3270°C is 8.41×10 -10 and 9.95×10 -8 kg/(cm²×s).

Among other materials, rhenium can be considered promising, the melting point of which is slightly lower than that of tungsten. Rhenium can be easily machined when heated, is resistant to oxidation, and has a lower evaporation rate than tungsten. There are foreign publications on the production of lamps with tungsten filament with rhenium additives, as well as coating the filament with a layer of rhenium. Of the non-metallic compounds, tantalum carbide is of interest, the evaporation rate of which is 20 - 30% lower than that of tungsten. An obstacle to the use of carbides, in particular tantalum carbide, is their fragility.

Table 2 shows the main physical properties of an ideal filament body made of tungsten.

table 2

Basic physical properties of tungsten filament

| Temperature, K | Evaporation rate, kg/(m²×s) | Electrical resistivity, 10 -6 Ohm×cm | Brightness cd/m² | Luminous efficacy, lm/W | Color temperature, K |

| 1000 1400 1800 2200 2600 3000 3400 | 5.32 × 10 -35 2.51 × 10 -23 8.81 × 10 -17 1.24 × 10 -12 8.41 × 10 -10 9.95×10 -8 3.47×10 -6 | 24,93 37,19 50,05 63,48 77,49 92,04 107,02 | 0,0012 1,04 51,2 640 3640 13260 36000 | 0,0007 0,09 1,19 5,52 14,34 27,25 43,20 | 1005 1418 1823 2238 2660 3092 3522 |

An important property of tungsten is the possibility of producing its alloys. Parts made from them retain a stable shape at high temperatures. When the tungsten wire is heated, during the heat treatment of the filament and subsequent heating, a change in its internal structure occurs, called thermal recrystallization. Depending on the nature of recrystallization, the filament body may have greater or less dimensional stability. The nature of recrystallization is influenced by impurities and additives added to tungsten during its manufacturing process.

The addition of thorium oxide ThO 2 to tungsten slows down the process of its recrystallization and provides a fine-crystalline structure. Such tungsten is strong under mechanical shocks, but it sags greatly and is therefore not suitable for the manufacture of filament bodies in the form of spirals. Tungsten with a high thorium oxide content is used to make cathodes for gas-discharge lamps due to its high emissivity.

For the manufacture of spirals, tungsten with an additive of silicon oxide SiO 2 is used together with alkali metals - potassium and sodium, as well as tungsten containing, in addition to those indicated, the additive of aluminum oxide Al 2 O 3. The latter gives the best results in the manufacture of bispirals.

The electrodes of most incandescent lamps are made of pure nickel. The choice is due to the good vacuum properties of this metal, which releases gases sorbed in it, high conductive properties and weldability with tungsten and other materials. The malleability of nickel allows welding with tungsten to be replaced by compression, which provides good electrical and thermal conductivity. In incandescent vacuum lamps, copper is used instead of nickel.

The holders are usually made of molybdenum wire, which retains elasticity at high temperatures. This allows the filament body to be maintained in an extended state even after it expands as a result of heating. Molybdenum has a melting point of 2890 K and a temperature coefficient of linear expansion (TCLE), in the range from 300 to 800 K equal to 55 × 10 -7 K -1. Molybdenum is also used to make inserts into refractory glass.

The terminals of incandescent lamps are made of copper wire, which is end-welded to the inputs. Low-power incandescent lamps do not have separate terminals; their role is played by elongated terminals made of platinite. To solder the leads to the base, tin-lead solder of the POS-40 brand is used.

Glass

Stems, plates, rods, flasks and other glass parts used in the same incandescent lamp are made of silicate glass with the same temperature coefficient of linear expansion, which is necessary to ensure the tightness of the welding points of these parts. The values of the temperature coefficient of linear expansion of lamp glasses must ensure the formation of consistent junctions with the metals used for the manufacture of bushings. The most widely used glass is the SL96-1 brand with a temperature coefficient value of 96 × 10 -7 K -1. This glass can operate at temperatures from 200 to 473 K.

One of the important parameters of glass is the temperature range within which it maintains weldability. To ensure weldability, some parts are made from SL93-1 glass, which differs from SL96-1 glass in its chemical composition and a wider temperature range in which it retains weldability. SL93-1 glass is characterized by a high content of lead oxide. If it is necessary to reduce the size of the flasks, more refractory glasses are used (for example, grade SL40-1), the temperature coefficient of which is 40 × 10 -7 K -1. These glasses can operate at temperatures from 200 to 523 K. The highest operating temperature is quartz glass of the SL5-1 brand, incandescent lamps from which can operate at 1000 K or more for several hundred hours (temperature coefficient of linear expansion of quartz glass is 5.4 × 10 -7 K -1). Glass of the listed brands is transparent to optical radiation in the wavelength range from 300 nm to 2.5 - 3 microns. The transmission of quartz glass starts at 220 nm.

Inputs

The bushings are made of a material that, along with good electrical conductivity, must have a thermal coefficient of linear expansion, ensuring the formation of consistent junctions with the glass used for the manufacture of incandescent lamps. The junctions of materials are called consistent, the values of the thermal coefficient of linear expansion of which over the entire temperature range, that is, from the minimum to the glass annealing temperature, differ by no more than 10 - 15%. When soldering metal into glass, it is better if the thermal coefficient of linear expansion of the metal is slightly lower than that of glass. Then, when the solder cools, the glass compresses the metal. In the absence of metal with the required value of the thermal coefficient of linear expansion, it is necessary to make unmatched joints. In this case, a vacuum-tight connection between metal and glass over the entire temperature range, as well as the mechanical strength of the solder, are ensured by a special design.

A matched junction with SL96-1 glass is obtained using platinum leads. The high cost of this metal led to the need to develop a substitute, called “platinite”. Platinite is a wire made of an iron-nickel alloy with a thermal coefficient of linear expansion lower than that of glass. By applying a layer of copper to such a wire, it is possible to obtain a highly conductive bimetallic wire with a large thermal coefficient of linear expansion, depending on the thickness of the layer of applied copper layer and the thermal coefficient of linear expansion of the original wire. Obviously, this method of matching the temperature coefficients of linear expansion makes it possible to match mainly the diametrical expansion, leaving the temperature coefficient of the longitudinal expansion unmatched. To ensure better vacuum density at the joints of SL96-1 glass with platinite and to enhance wettability over a layer of copper oxidized over the surface to cuprous oxide, the wire is coated with a layer of borax (sodium salt of boric acid). Sufficiently strong solders are ensured when using platinum wire with a diameter of up to 0.8 mm.

Vacuum-tight soldering into SL40-1 glass is obtained using molybdenum wire. This pair gives a more consistent connection than SL96-1 glass with platinite. The limited use of this solder is due to the high cost of raw materials.

To obtain vacuum-tight leads in quartz glass, metals with a very low thermal coefficient of linear expansion are required, which do not exist. Therefore, I get the required result thanks to the input design. The metal used is molybdenum, which has good wettability with quartz glass. For incandescent lamps in quartz flasks, simple foil bushings are used.

Gases

Filling incandescent lamps with gas allows you to increase the operating temperature of the filament body without reducing the service life due to a decrease in the rate of tungsten sputtering in a gaseous environment compared to sputtering in a vacuum. The atomization rate decreases with increasing molecular weight and filling gas pressure. The filling gas pressure is approximately 8 × 104 Pa. What gas should I use for this?

The use of a gas medium leads to heat losses due to thermal conductivity through the gas and convection. To reduce losses, it is advantageous to fill lamps with heavy inert gases or their mixtures. These gases include nitrogen, argon, krypton and xenon obtained from air. Table 3 shows the main parameters of inert gases. Nitrogen in its pure form is not used due to large losses associated with its relatively high thermal conductivity.

Table 3

Basic parameters of inert gases

An incandescent lamp is a lighting device, an artificial light source. Light is emitted by a heated metal coil when an electric current flows through it.

Operating principle

An incandescent lamp uses the effect of heating a conductor (filament) when electric current flows through it. The temperature of the tungsten filament increases sharply after turning on the current. The thread emits electromagnetic radiation in accordance with the law Plank. The Planck function has a maximum, the position of which on the wavelength scale depends on temperature. This maximum shifts with increasing temperature towards shorter wavelengths (shift law Guilt). To obtain visible radiation, the temperature must be on the order of several thousand degrees, ideally 6000 K (surface temperature Sun). The lower the temperature, the lower the proportion of visible light and the more “red” the radiation appears.

The incandescent lamp converts part of the electrical energy consumed into radiation, while part is lost as a result of the processes of thermal conductivity and convection. Only a small fraction of the radiation lies in the region of visible light, the main portion comes from infrared radiation. To increase the efficiency of the lamp and obtain the most “white” light, it is necessary to increase the temperature of the filament, which in turn is limited by the properties of the filament material - the melting point. The ideal temperature of 6000 K is unattainable, because at this temperature any material melts, collapses and ceases to conduct electric current. Modern incandescent lamps use materials with maximum melting points - tungsten (3410 °C) and, very rarely, osmium (3045 °C).

At practically achievable temperatures of 2300–2900 °C, the light emitted is far from white and not daylight. For this reason, incandescent light bulbs emit light that appears more "yellow-red" than daylight. To characterize the quality of light, the so-called Colorful temperature.

In ordinary air at such temperatures, tungsten would instantly turn into oxide. For this reason, the tungsten filament is protected by a glass bulb filled with a neutral gas (usually argon). The first light bulbs were made with evacuated bulbs. However, in a vacuum at high temperatures, tungsten quickly evaporates, making the filament thinner and darkening the glass bulb when deposited on it. Later, flasks began to be filled with chemically neutral gases. Vacuum flasks are now used only for low-power lamps.

Design

An incandescent lamp consists of a base, contact conductors, a filament, a fuse and a glass bulb that protects the filament from the environment.

Flask

The glass bulb protects the thread from combustion in the surrounding air. The dimensions of the flask are determined by the deposition rate of the filament material. Higher power lamps require larger bulbs so that the deposited filament material is distributed over a larger area and does not have a strong effect on transparency.

Buffer gas

The bulbs of the first lamps were evacuated. Modern lamps are filled with a buffer gas (except for low-power lamps, which are still made vacuum). This reduces the rate of evaporation of the filament material. The heat losses arising due to thermal conductivity are reduced by choosing a gas with the heaviest molecules possible. Mixtures of nitrogen and argon are an accepted compromise in terms of cost reduction. More expensive lamps contain krypton or xenon (atomic weights: nitrogen: 28.0134 g/mol; argon: 39.948 g/mol; krypton: 83.798 g/mol; xenon: 131.293 g/mol)

Filament

The filament in the first light bulbs was made of coal (sublimation point 3559 °C). Modern light bulbs use almost exclusively osmium-tungsten alloy filaments. The wire is often shaped like a double helix in order to reduce convection by reducing the Langmuir layer.

Lamps are manufactured for various operating voltages. The current strength is determined by Ohm's law (I = U / R) and power by the formula P = U\cdot I, or P = U2 / R. With a power of 60 W and an operating voltage of 230 V, a current of 0.26 A should flow through the light bulb, i.e., the resistance of the filament should be 882 Ohms. Since metals have low resistivity, a long and thin wire is needed to achieve such resistance. The thickness of the wire in conventional light bulbs is 40-50 microns.

Since when turned on, the filament is at room temperature, its resistance is much less than the operating resistance. Therefore, when turned on, a very large current flows (two to three times the operating current). As the filament heats up, its resistance increases and the current decreases. Unlike modern lamps, early incandescent lamps with carbon filaments worked on the opposite principle when turned on - when heated, their resistance decreased and the glow slowly increased.

In flashing light bulbs, a bimetallic switch is built in series with the filament. Due to this, such light bulbs operate independently in flashing mode.

Base

The threaded base shape of a conventional incandescent lamp has been proposed Thomas Alva Edison. The sizes of the socles are standardized.

Fuse

A fuse (a piece of thin wire) located in the base of an incandescent lamp is designed to prevent an electric arc from occurring when the lamp burns out. For household lamps with a rated voltage of 220 V, such fuses are usually rated for a current of 7 A.

Efficiency and durability

Almost all the energy supplied to the lamp is converted into radiation. Losses due to thermal conductivity and convection are small. However, only a small range of wavelengths of this radiation is accessible to the human eye. The bulk of the radiation lies in the invisible infrared range, and is perceived as heat. The efficiency of incandescent lamps reaches its maximum value of 15% at a temperature of about 3400 K. At practically achievable temperatures of 2700 K, the efficiency is 5%.

As the temperature increases, the efficiency of an incandescent lamp increases, but at the same time its durability decreases significantly. At a filament temperature of 2700 K, the lamp life is approximately 1000 hours, at 3400 K only a few hours. When the voltage increases by 20%, the brightness doubles. At the same time, the lifetime is reduced by 95%.

Reducing the voltage by half (for example, when connected in series), although it reduces the efficiency, but increases the lifetime by almost a thousand times. This effect is often used when it is necessary to provide reliable emergency lighting without special requirements for brightness, for example, on landings.

The limited lifetime of an incandescent lamp is due to a lesser extent to the evaporation of the filament material during operation, and to a greater extent to the inhomogeneities that arise in the filament. Uneven evaporation of the filament material leads to the appearance of thinned areas with increased electrical resistance, which in turn leads to even greater heating and evaporation of the material in such places. When one of these constrictions becomes so thin that the filament material at that point melts or completely evaporates, the current is interrupted and the lamp fails.

Halogen lamps

Adding bromine or iodine halogens to the buffer gas increases the lamp life to 2000–4000 hours. In this case, the operating temperature is approximately 3000 K. The efficiency of halogen lamps reaches 28 lm/W.

Iodine (together with residual oxygen) enters into a chemical combination with the evaporated tungsten atoms. This process is reversible - at high temperatures the compound breaks down into its constituent substances. Tungsten atoms are released in this way either on the helix itself or near it.

The addition of halogens prevents the deposition of tungsten on the glass, provided that the glass temperature is greater than 250 °C. Due to the absence of blackening of the bulb, halogen lamps can be manufactured in a very compact form. The small volume of the flask allows, on the one hand, to use a higher operating pressure (which again leads to a decrease in the rate of evaporation of the filament) and, on the other hand, without a significant increase in cost, to fill the flask with heavy inert gases, which leads to a reduction in energy losses due to thermal conductivity. All this extends the life of halogen lamps and increases their efficiency.

Due to the high temperature of the flask, any surface contaminants (for example, fingerprints) quickly burn out during operation, leaving black marks. This leads to local increases in the temperature of the flask, which can cause its destruction. Also, due to the high temperature, the flasks are made of quartz.

A new direction in the development of lamps is the so-called. IRC halogen lamps (IRC stands for infrared coating). A special coating is applied to the bulbs of such lamps, which allows visible light to pass through, but retains infrared (thermal) radiation and reflects it back to the spiral. Due to this, heat loss is reduced and, as a result, the efficiency of the lamp increases. According to OSRAM, energy consumption is reduced by 45% and the lifetime is doubled (compared to a conventional halogen lamp).

Although IRC halogen lamps do not achieve the efficiency of fluorescent lamps, their advantage is that they can be used as a direct replacement for conventional halogen lamps.

Special lamps

Projection lamps - for slide and film projectors. They have an increased filament temperature (and, accordingly, increased brightness and reduced service life); Usually the thread is placed so that the luminous area forms a rectangle.

Double-filament lamps for car headlights. One thread for high beam, the other for low beam. In addition, such lamps contain a screen that, in low beam mode, cuts off rays that could blind oncoming drivers.

History of invention

In 1854, a German inventor Heinrich Goebel developed the first "modern" light bulb: a charred bamboo filament in an evacuated container. Over the next 5 years, he developed what many call the first practical light bulb.

July 11, 1874 Russian engineer Alexander Nikolaevich Lodygin received patent number 1619 for a filament lamp. He used a carbon rod placed in an evacuated vessel as a filament.

English inventor Joseph Wilson Swan received a British patent for a carbon filament lamp in 1878. In his lamps, the filament was in a rarefied oxygen atmosphere, which made it possible to obtain very bright light.

In the second half of the 1870s, the American inventor Thomas Edison conducts research work in which he tries various metals as threads. Eventually he returns to carbon fiber and creates a light bulb with a lifespan of 40 hours. Despite such a short lifespan, its light bulbs are replacing the gas lighting used until then.

In the 1890s, Lodygin invents several types of lamps with metal filaments.

In 1906, Lodygin sold a patent for a tungsten filament to General Electric. Due to the high cost of tungsten, the patent finds only limited use.

In 1910 William David Coolidge invents an improved method for producing tungsten filament. Subsequently, the tungsten filament displaces all other types of filaments.

The remaining problem with the rapid evaporation of filament in a vacuum was solved by an American scientist Irving Langmuir, who, having worked in the company since 1909 General Electric, came up with the idea of filling lamp bulbs with inert gas, which significantly increased the life of the lamps.

Hi all. Glad to see you on my website. The topic of today's article: the design of an incandescent lamp. But first I would like to say a few words about the history of this lamp.

The very first incandescent light bulb was invented by the English scientist Delarue back in 1840. She had a platinum spiral. A little later, in 1854, the German scientist Heinrich Goebel introduced a lamp with a bamboo thread, which was located in a vacuum flask. At that time, there were still a lot of different lamps presented by different scientists. But they all had a very short service life and were ineffective.

In 1890, the scientist A.N. Lodygin first introduced a lamp whose filament was made of tungsten and had the shape of a spiral. This scientist also attempted to pump air out of the flask and fill it with gases. This significantly increased the service life of the lamps.

But mass production of incandescent lamps began already in the 20th century. Back then it was a real breakthrough in technology. Now, in our time, many enterprises, and just ordinary people, refuse these lamps due to the fact that they consume a lot of electricity. And in some countries they even banned the production of incandescent lamps with a power of more than 60 watts.

Incandescent lamp device.

Such a lamp consists of the following parts: base, bulb, electrodes, hooks for holding the filament, filament, stem, insulating material, contact surface.

To make it more clear to you, I will now write about each detail separately. Also see the picture and video.

The bulb is made of ordinary glass and is needed to protect the filament from the external environment. A rod with electrodes and hooks that hold the thread itself is inserted into it. A vacuum is specially created in the flask, or it is filled with a special gas. This is usually argon, as it cannot be heated.

On the side where the electrode leads are located, the flask is melted with glass and glued to the base.

The socket is needed so that the light bulb can be screwed into the socket. It is usually made of aluminum.

A filament is a part that emits light. It is made mainly from tungsten.

And now, to consolidate your knowledge, I suggest you watch a very interesting video that tells and shows how incandescent lamps are made.

Operating principle.

The operating principle of an incandescent lamp is based on heating the material. It’s not for nothing that the filament has such a name. If you pass an electric current through a light bulb, the tungsten filament heats up to a very high temperature and begins to emit light.

The thread does not melt because tungsten has a very high melting point, somewhere around 3200-3400 degrees Celsius. And when the lamp is operating, the filament heats up to somewhere around 2600-3000 degrees Celsius.

Advantages and disadvantages of incandescent lamps.

Main advantages:

Not a high price.

Small dimensions.

They can easily withstand voltage fluctuations in the network.

When turned on, it lights up instantly.

Flicker is almost imperceptible to the human eye when operating from an AC source.

You can use the device to adjust the brightness.

Can be used at both low and high ambient temperatures.

Such lamps can be produced for almost any voltage.

It does not contain hazardous substances and therefore does not require special disposal.

No starting devices are needed to light the lamp.

Can operate on alternating and direct voltage.

It works very quietly and does not create radio interference.

And this is not a complete list of advantages.

Flaws:

Has a very short service life.

Very low efficiency. Usually it does not exceed 5 percent.

Luminous flux and service life directly depend on the network voltage.

The lamp body becomes very hot during operation. Therefore, such a lamp is considered a fire hazard.

If the thread breaks, the flask may explode.

Very fragile and sensitive to shock.

In vibration conditions it fails very quickly.

And at the end of the article I would like to write about one amazing fact. In the USA, in one of the fire departments in the city of Livermore, there is a 60-watt lamp that has been glowing continuously for more than 100 years. It was lit back in 1901, and in 1972 it was included in the Guinness Book of Records.

The secret of its longevity is that it works in deep underwater conditions. By the way, the operation of this lamp is continuously recorded by a webcam. So if you are interested, you can look for the live broadcast on the Internet.

That's all I have. If the article was useful to you, then share it with your friends on social networks and subscribe to updates. Bye.

Sincerely, Alexander!

The Planck function has a maximum, the position of which on the wavelength scale depends on temperature. This maximum shifts with increasing temperature towards shorter wavelengths (Wien's displacement law). To obtain visible radiation, the temperature must be on the order of several thousand degrees, ideally 5770 (the temperature of the surface of the Sun). The lower the temperature, the lower the proportion of visible light and the more “red” the radiation appears.

36 W incandescent lamp

The incandescent lamp converts part of the electrical energy consumed into radiation, while part is lost as a result of the processes of thermal conductivity and convection. Only a small fraction of the radiation lies in the region of visible light, the main share comes from infrared radiation. To increase the efficiency of the lamp and obtain the most “white” light, it is necessary to increase the temperature of the filament, which in turn is limited by the properties of the filament material - the melting point. The ideal temperature of 5770 K is unattainable, because at this temperature any known material melts, breaks down and ceases to conduct electric current. Modern incandescent lamps use materials with maximum melting points - tungsten (3410 °C) and, very rarely, osmium (3045 °C).

At practically achievable temperatures of 2300-2900 °C, the light emitted is far from white and not daylight. For this reason, incandescent light bulbs emit light that appears more "yellow-red" than daylight. To characterize the quality of light, the so-called Colorful temperature .

In ordinary air at such temperatures, tungsten would instantly turn into oxide. For this reason, the tungsten filament is protected by a glass bulb filled with a neutral gas (usually argon). The first lamps were made with evacuated bulbs. However, in a vacuum at high temperatures, tungsten quickly evaporates, making the filament thinner (which leads to its rapid burnout) and darkening the glass bulb when deposited on it. Later, flasks began to be filled with chemically neutral gases. Vacuum flasks are now used only for low-power lamps.

Design

An incandescent lamp consists of a base, contact conductors, a filament, a fuse and a glass bulb filled with a buffer gas and protecting the filament from the environment.

Flask

The glass bulb protects the thread from combustion in the surrounding air. The dimensions of the flask are determined by the deposition rate of the filament material. Higher power lamps require larger bulbs so that the deposited filament material is distributed over a larger area and does not have a strong effect on transparency.

Buffer gas

The bulbs of the first lamps were evacuated. Modern lamps are filled with a buffer gas (except for low-power lamps, which are still made vacuum). This reduces the rate of evaporation of the filament material. Heat losses arising due to thermal conductivity are reduced by choosing a gas with, if possible, the heaviest molecules. Mixtures of nitrogen and argon are an accepted compromise in terms of cost reduction. More expensive lamps contain krypton or xenon (molar masses: nitrogen: 28.0134 /mol; argon: 39.948 /mol; krypton: 83.798 /mol; xenon: 131.293 /mol)

Filament

Double filament incandescent lamp (Osram 200 W) with contact conductors and filament holders

Since the filament is at room temperature when turned on, its resistance is an order of magnitude less than the operating resistance. Therefore, when turned on, a very large current flows (ten to fourteen times the operating current). As the filament heats up, its resistance increases and the current decreases. Unlike modern lamps, early incandescent lamps with carbon filaments worked on the opposite principle when turned on - when heated, their resistance decreased and the glow slowly increased.

In flashing lamps, a bimetallic switch is built in series with the filament. Due to this, such lamps operate independently in flashing mode.

Base

In order to open the circuit when an arc ignites and prevent overload of the supply circuit, a fuse is provided in the lamp design. It is a piece of thin wire and is located in the base of an incandescent lamp. For household lamps with a rated voltage of 220, such fuses are usually rated for a current of 7.

Efficiency and durability

Durability and brightness depending on operating voltage

Almost all the energy supplied to the lamp is converted into radiation. Losses due to thermal conductivity and convection are small. However, only a small range of wavelengths of this radiation is accessible to the human eye. The bulk of the radiation lies in the invisible infrared range and is perceived as heat. The efficiency of incandescent lamps reaches its maximum value of 15% at a temperature of about 3400. At practically achievable temperatures of 2700, the efficiency is 5%.

As the temperature increases, the efficiency of an incandescent lamp increases, but at the same time its durability decreases significantly. At a filament temperature of 2700, the lamp life is approximately 1000 hours, at 3400 only a few hours. As shown in the figure on the right, when the voltage increases by 20%, the brightness doubles. At the same time, the lifetime is reduced by 95%.

Reducing the supply voltage, although it reduces efficiency, but increases durability. So, lowering the voltage by half (for example, when connected in series) greatly reduces the efficiency, but it increases the lifetime by almost a thousand times. This effect is often used when it is necessary to provide reliable emergency lighting without special brightness requirements, for example, on staircase landings. Often, for this purpose, when powered by alternating current, the lamp is connected in series with a diode, due to which current flows into the lamp only during half the period.

The limited lifetime of an incandescent lamp is due to a lesser extent to the evaporation of the filament material during operation, and to a greater extent to the inhomogeneities that arise in the filament. Uneven evaporation of the filament material leads to the appearance of thinned areas with increased electrical resistance, which in turn leads to even greater heating and evaporation of the material in such places. When one of these constrictions becomes so thin that the filament material at that point melts or completely evaporates, the current is interrupted and the lamp fails.

The majority of filament wear occurs when voltage is suddenly applied to the lamp, so its service life can be significantly increased by using various types of soft starters. A tungsten filament has a cold resistivity that is only 2 times higher than that of aluminum. When a lamp burns out, it often happens that the copper wires that connect the base contacts to the spiral holders burn out. Thus, a regular 60 W lamp consumes over 700 W when switched on, and a 100 W lamp consumes more than a kilowatt. As the coil warms up, its resistance increases, and the power drops to its nominal value.

To smooth out peak power, thermistors with a strongly decreasing resistance as they warm up, or reactive ballast in the form of capacitance or inductance can be used. The voltage on the lamp increases as the coil warms up and can be used to automatically bypass the ballast. Without turning off the ballast, the lamp can lose from 5 to 20% of power, which can also be beneficial for increasing the resource.

| type | Efficiency | Light output(Lumen/Watt) |

|---|---|---|

| 40 W Incandescent lamp | 1.9 % | 12.6 |

| 60 W Incandescent lamp | 2.1 % | 14.5 |

| 100 W Incandescent lamp | 2.6 % | 17.5 |

| Halogen lamps | 2.3 % | 16 |

| Metal halide lamp (with quartz glass) | 3.5 % | 24 |

| High temperature incandescent lamp | 5.1 % | 35 |

| Absolute black body at 4000 K | 7.0 % | 47.5 |

| Absolute blackbody at 7000 K | 14 % | 95 |

| Perfect white light source | 35.5 % | 242.5 |

| Ideal monochromatic 555 nm (green) source | 100 % | 683 |

Halogen lamps

Halogen lamp

A new direction in the development of lamps is the so-called. IRC-halogen lamps (the abbreviation IRC stands for “infrared coating”). A special coating is applied to the bulbs of such lamps, which allows visible light to pass through, but retains infrared (thermal) radiation and reflects it back to the spiral. Due to this, heat loss is reduced and, as a result, the efficiency of the lamp increases. According to the company.

Although IRC halogen lamps do not achieve the efficiency of fluorescent lamps, their advantage is that they can be used as a direct replacement for conventional halogen lamps.

Special lamps

- Projection lamps - for slide and film projectors. They have increased brightness (and, accordingly, increased filament temperature and reduced service life); Usually the thread is placed so that the luminous area forms a rectangle.

- Double-filament lamps for car headlights. One thread for high beam, the other for low beam. In addition, such lamps contain a screen that, in low beam mode, cuts off rays that could blind oncoming drivers.

History of invention

Thomas Alva Edison