Classification of shut-off valves. What are the markings of valves, their designations Scope of application of shut-off valves

Valves are a locking mechanism on pipelines for various purposes and serve to shut off or partially limit the amount of substance transported through them. And the normal functioning of the entire backbone system depends on the quality of these devices.

Valves marking

Their symbol consists of certain letters and numbers, which indicate the material from which the body and individual sealing elements are made. To understand the rules for deciphering valves, it is necessary to examine in detail the markings of the existing device.

30s41nzh Du150:

- 30 - designation of fittings, in this case a valve (maybe 31).

- c - type of material from which the body is made - carbon steel. There are also: h (cast iron), nzh (stainless steel), B (bronze), p (plastic), tn (titanium alloy), ls (alloy steel).

- 41 - model number.

- nzh - decoding of the material of the sealing parts - stainless steel.

- DN150 is the working diameter, this value may vary.

Varieties

The most common types are:

- Valves with a rubberized wedge - the supply of water or other liquid is shut off in the direction perpendicular to its movement. The valve is a wedge-shaped disc located between the O-rings

- Parallel - the design involves the use of 1 or 2 special discs as a locking mechanism.

These are the main varieties that are intended for installation primarily on water mains. They also exist for transporting gaseous substances, steam, petroleum products, etc.

Gate valves can be made of cast iron and steel.

Cast iron devices

As a rule, they consist of a body and a wedge-shaped locking element that moves along the sealing surfaces when closing. They are characterized by low hydraulic resistance. They can only be connected to the pipeline using flange connectors.

They are divided into full bore, their diameter coincides with the pipe on which they are installed, and narrowed - their cross-section is smaller than the diameter of the pipeline. The design of narrowed devices greatly facilitates the process of controlling shut-off valves and reduces their weight and overall dimensions, and also allows you to regulate the pressure.

Steel valves

They differ in that the valve can only shut off or connect the water supply; it is impossible to regulate the pressure with their help. The pipeline is connected to both a coupling and a flange connection.

For pipelines for different purposes, different types of shut-off valves are used. In order to correctly select a device for a particular pipeline system, you need to know the purpose of the fittings and its technical characteristics. Let's look at the main types of locking devices in more detail.

Scope of application of shut-off valves

Shut-off valves are intended:

- for pipelines supplying gas or water to residential, domestic and industrial premises and discharging sewage. This is the widest scope of application of locking devices;

- for pipelines carrying aggressive substances. Devices for the chemical and oil and gas industries will demand higher tightness and corrosion resistance;

- household networks, heat supply and sewerage. The fittings installed on private networks are small in size and easy to manage.

Only fittings that are intended specifically for this type can be installed on the pipeline.

Types of shut-off valves

The following types of shut-off pipeline valves are distinguished:

- taps;

- gates (valves);

- valves;

- flaps.

Crane classification

Shut-off valves are primarily designed for low-pressure domestic pipelines.

The shut-off valve design is as follows:

- frame;

- locking element;

- handle;

- set of sealing gaskets.

Devices can be classified according to several criteria:

- type of locking element;

- installation method.

An element that blocks the flow of a passing medium can be:

- ball. In accordance with this, the valve is called a ball valve (figure above);

- cone in the form of a plug (plug valve).

The taps can be attached to the pipeline:

- coupling method. The fixing nuts are screwed onto the thread prepared on the pipe;

- flange method. The fixing elements are flanges connected to each other with bolts;

- welding method.

Each tap has its own symbol. The markings on the device body must include:

- nominal diameter (DN);

- conditional pressure for which the device is designed (PN);

- material used to make the tap;

- manufacturer;

- additional reference materials (date of manufacture, batch number, etc.).

If you know the markings, you can always choose a locking device yourself.

Using Gates

The shut-off valve () consists of a body with two ends for attaching the device and a seat that is closed by a shutter.

The main distinguishing feature of a valve from a faucet is its high tightness class, which allows the device to be used on gas pipelines.

A valve, like a faucet, can be connected to a pipeline using couplings, flanges or welding.

Valves are produced that are actuated by:

- flywheel (manual control);

- electric drive (electronic control), including using a remote control.

The marking of shut-off valves also contains:

- symbol of the device model;

- passage;

- designation of the type of connection to the pipeline;

- pressure;

- execution material;

- Climatic performance;

- document on the basis of which the valve is manufactured.

Purpose and types of valves

The most commonly used element of any pipeline is the valve. The device consists of a body and a cover, between which the shutter is located.

The purpose of shut-off valves - valves - is any pipelines whose diameter varies from 15 mm to 2000 mm.

The advantages of the device, compared to other types of shut-off valves, are:

- ease of maintenance and design;

- small sizes;

- low resistance.

Gate valves can be made from the following materials:

- become;

- cast iron;

- non-ferrous metals and alloys made from them.

The valves are controlled:

- manually (rotating the handle);

- electric drive;

- hydraulic drive.

Valves with electric or hydraulic drive are mainly installed on industrial pipelines.

The designation of shut-off valves (valve) determines:

- type and name of the device;

- nominal working diameter;

- maximum pressure in the system;

- type of drive;

- position of the device in working condition;

- accommodation category;

- Climatic performance;

- type of connection of the device to the pipeline.

Purpose of dampers

The closing element in the damper is a disk that rotates around an axis.

Valves are mainly used on pipelines that have a large diameter and are under low pressure, since the tightness class of the device is quite low.

The damper can be controlled:

- a flywheel that drives the axis of rotation (manual control);

- hydraulic drive;

- electric drive.

In most cases, the body of the locking device is made of cast iron, and the rotary disk is made of steel.

Dampers are installed:

- welding method;

- flange fasteners.

The valves can be used in chemical pipelines and sewer systems. They are practically not used for water supply or heating.

The brand of shut-off valves - valves, as well as the batch number, diameter, pressure and area of definition are indicated on the device body similarly to the previously given diagrams.

Symbols of shut-off valves

Each type and subtype of shut-off valves used in pipeline construction has its own symbol, which makes it easier for builders to select a device.

For example, a gate valve is denoted by two triangles connected by vertices.

How other fittings are designated is indicated in the figure below.

Thus, each type of shut-off valve is intended for specific pipelines. To select the most suitable device, you can use the markings that are applied to the product body or indicated in the pipeline diagram.

Add material

Current comment!

Designations of pipeline fittings

Pipe fittings (symbols)

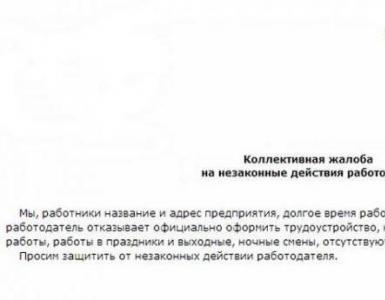

With all the variety of pipeline fittings (brands, designations, types, materials), selection for specific use parameters is simplified by using a system of symbols in which some of the main technical parameters of the product are briefly recorded.

Existing index systems provide the ability to correctly select fittings for use during installation and operation in engineering systems.

The most widely used system is the TsKBA (Central Design Bureau for Valve Manufacturing), which contains a digital and alphabetic code for the basic data of valves (table-figure).

Also, along with the TsKBA system, they use a code obtained by abbreviating the name of the product, for example, KSh - ball valve or KTS – three-way steel valve.

Also, some manufacturers use designation systems different from TsKBA. In these systems, letters can be used that begin with the designation of the drawing number of the fittings (based on the name of the manufacturer’s company that developed the product design), and the first two digits are the type and design.

But in any case, the TsKBA designation system is additionally indicated.

TsKBA system

According to the TsKBA system, the product index includes five elements arranged in series (in the absence of a drive, the product index consists of four elements).

The first two digits indicate the type of fittings (Table 1),

Table 1: Type of fittings

Type of fittings

Symbol

Valve (for pipeline)

Level indicator locking device

Non-return valve (lift or intake valve with mesh)

Check valve (rotary check valve), sealed valve

Butterfly valve

Housing material

Symbol

Plastics (except vinyl plastic)

one or two digits after the letters - model number (design features of the product), if there are three digits: the first of them indicates the type of drive (Table 3)

Table 3: Drive type

Drive unit

Symbol

Under remote control

Mechanical with worm gear

Same with spur gears

Same with bevel gear

Sealing surface material

Symbol

Corrosion-resistant (stainless) steel

Plastics (except vinyl plastic)

or the method of applying the internal coating of the body (Table 5).

Table 5 Housing coating

Internal coating method

Symbol

In some cases, after the letters indicating the material of the sealing surfaces, a number is added that indicates the version of this product or its manufacture from a different material. A product without inserted or welded-on rings, that is, with sealing surfaces made directly on the body or valve, is designated by the letters “bk” (without rings).

15s41nzh Steel shut-off valve made of carbon steel without electric drive

15 – according to table 1 – shut-off valve

41 – model number

NZ – according to Table 4 – sealing surfaces overlaid with corrosion-resistant steel

For valves with electric drives in an explosion-proof design, the letter B is added at the end of the symbol (for example, 30ch906brB), and in a tropical version - the letter T (for example, 30ch906brT). The letters B and T are indicated when ordering.

Along with the TsKBA system, they use a code obtained by abbreviating the name of the product, for example, KTS - three-way steel valve, etc. Individual structures are identified only by the number of the drawing according to which they are manufactured. Sometimes a letter is entered into the designation indicating the manufacturer of the fittings.

The symbol for valves intended for the oil refining and oil production industries consists of letters and numbers. The letters indicate the type of valve, the numbers behind the letters indicate the product parameters, for example, ZKL-200-16 - a cast wedge valve with a nominal bore of 200 mm, for a nominal pressure of 16 kgf/cm2 or KP-160 - a feed valve for a nominal pressure of 160 kgf/cm2 . Products that do not have a symbol are designated by the drawing number.

Additional information on the classification of pipeline fittings is provided in the article: CLASSIFICATION OF PIPELINE FITTINGS and graphic symbols of pipeline fittings

Marking of shut-off valves

To make shutoff valves convenient to classify, store and sell, they are marked and designated in a certain way. At the same time, the marking of shut-off valves, on the one hand, should not take up much space on the product, on the other hand, it should be as informative as possible for the consumer and manufacturer. Today, all existing types of domestic shut-off valves are marked in accordance with Russian legislation (GOSTs).

Marking of shut-off valves must include:

Trademark or manufacturer's name;

nominal diameter, mm. Here we mean the conditional (nominal) diameter. It is designated as DN (DN), followed by the diameter value without a space;

conditional pressure, MPa. Nominal pressure. Designated as Ru or PN. In addition to pressure, it is possible to indicate the operating temperature range;

direction of the medium flow. Indicated by an arrow on the body. It is applied at the stage of casting and stamping;

brand of body material. The materials of the body and shutter are marked as follows: NZ – stainless steel, LS – alloy steel, h – gray cast iron. Sealing surfaces: br - bronze, brass, p - plastic, p - rubber.

How are shut-off valves marked?

In accordance with domestic GOSTs, the marking of shut-off valves is applied directly to the product body. All information about a specific model is applied on the front side, and the manufacturer’s mark is on the back. Marking of shut-off valves on the metal surface of the body is applied in three main ways:

stamping. Represents the process of deformation of a material. This embossing creates letters and numbers on the surface of the valve body. The durability of this embossing is the same as that of the reinforcement itself;

engraving. It is one of the oldest methods of applying inscriptions to metals. Engraving can be found on pre-revolutionary valves and taps. Letters and numbers are applied using a cutter, which can be a graver, a milling cutter, or a punch (looks like a nail);

branding. It is a rather complex process that will require a certain skill and professionalism from the performer. For application, special equipment is used - an electric spark pencil. This method is used quite rarely.

It should be noted that, depending on the material of the body parts, the outer surfaces of the shut-off valves can be painted in the appropriate color:

blue painting means alloy steel;

blue – corrosion steel;

black paint color corresponds to gray malleable cast iron;

gray – carbon steel.

Let us describe the marking of shut-off valves using the example of products from the Admiral plant:

19s63nzh. The number 19 means a non-return valve, a sealed valve. The small letter "c" means the body is made of carbon steel. The letters “NZ” indicate that the sealing surfaces in the product are made of stainless steel;

30nzh541nzh. “30” means that the shut-off valve is a gate valve type. “NZH” – the body is made of stainless steel. “5” means that the control method uses a mechanical control method with a bevel gear. “41” is the model number. “NZH” – the sealing surfaces in the product are made of stainless steel;

32s908r. “32” – the product is a butterfly valve. “c” – made of carbon steel. “9” – controlled by an electric drive. Model number 08. “p” - sealing surfaces are made of rubber.

The Admiral plant pays due attention to the marking of shut-off valves. Moreover, this is done not only to make life easier for the consumer and operator of the product, but also to make it easier to store products in the enterprise’s warehouses and distribute them to representative offices and sales points. Markings make it easy to classify the fittings.

Clear, clearly visible markings on shut-off valves make handling them simpler and more convenient. This applies to both purchase and delivery, as well as further maintenance, repairs, and the purchase of spare parts for it. Poorly visible markings can ultimately lead to incorrect replacement of the part and complete failure of the product.

Marking of shut-off valves is applied at the final stage of production, but before testing procedures. If a defect is detected, the model will not be lost and will be quickly modified (corrected). Marking is applied by qualified specialists using modern equipment. Quality labeling is a sign of good reputation and responsibility of the manufacturer.

Marking of shut-off valves

Marking of shut-off valves: what should be included, how it is carried out. Decoding the markings of shut-off valves.

Classification of shut-off valves

Devices installed on pipelines, called pipeline fittings, are designed for a variety of purposes - control, regulation, protection, monitoring and many other functions. For a more understandable designation, pipeline and shut-off valves were classified as units by sections to clarify operational properties, functions and purposes. The standard for definitions and terms for pipeline fittings - GOST 24856-2014 was adopted on May 30, 2014. It was agreed upon and approved by Russia, Belarus, Armenia, Kyrgyzstan, Uzbekistan and Ukraine. The interstate standard has been in force in the Russian Federation since April 1, 2015 and includes definitions and terms; the classification of pipeline shut-off valves is divided into a fairly large number of main types:

- Shut-off valves are devices used for periodic or one-time inclusion or shutdown of a part of a pipeline or object (valves, valves, gate valves, taps, etc.

- Control valves are devices used to partially block flow sections and change the amount of flowing liquid in order to regulate flow rates, pressure, level, temperature, medium composition, etc.;

- Safety valves are devices used to limit operating parameters and prevent emergency conditions: releasing excess medium in case of excessive pressure increase (safety and bypass valves), preventing the movement of the medium in the opposite direction (check valves);

- Control valves - devices designed to determine the presence or level of liquid (test valves, level indicators);

- Various fittings are devices used, for example, to drain one of the phases of the medium: condensate (condensate drains), air (plungers), oil (oil separators), etc.

In addition, shut-off valves can be classified into the following types:

- According to the method of application - the areas of application in a particular production environment of shut-off valves can vary dramatically, therefore the valves are divided into: industrial, special, marine, sanitary fittings

- By structural types of fittings - in this classification, types of fittings are divided depending on their design features (gate valves, valves, taps, valves)

- By connection method - in this case, the method of connecting the fittings to the pipeline is considered (connection using couplings, flanges, fittings or welding)

- According to the method of sealing the fittings - relative to the external environment (stuffing box, membrane, hose, bellows fittings)

- According to the method of controlling the valves. From the point of view of control method, valves are divided into remote controlled valves, automatically controlled valves and manually controlled valves

The main parameters by which one or another shut-off valve is selected are:

- Nominal passage diameter Dy – internal diameter of the pipeline to which the fittings are connected

- Operating pressure P – pressure at which the valve is operated

- Conditional medium pressure Ru - nominal medium pressure, usually corresponding to the working pressure at a medium temperature t = 0-120 0C for cast iron fittings and t = 0-200 0C for carbon steel fittings

- Test pressure is the pressure at which a hydraulic strength test of the fittings is performed.

In our company, it is customary to designate all manufactured products with general industrial markings in accordance with international standards. This is done for more convenient product identification and a brief description of the product. The designations can be deciphered as follows:

All shut-off valves according to classification have a standard type of designation XXaaYYbb

Where XX and YY have a digital designation

aa and bb letter designation

“XX” the first digits indicate the type of fittings:

- 10 – tap (trial run)

- 11- tap (for pipeline)

- 12 – level indicator locking device

- 13,14,15 – shut-off valves (gates) of various types and designs.

- 22.24 – shut-off valve

- 16 – check valve

- 17 – safety valve

- 19 – check valve, sealed valve

- 20 – bypass valve

- 18.21 – pressure regulator

- 23 – distribution valve

- 27 – mixing valve

- 30.31 – valve

- 32 – rotary shutter

- 33 – hose valve

- 40 – elevator

- 45 – condensate drain

The type of pipeline shut-off valve briefly indicates the purpose, main design and functional features of the devices.

Then follow the letters “aa”, they indicate the material of the body parts.

- C – Carbon steel

- LS – alloy steel

- NJ – stainless steel

- H – gray cast iron

- KCh – malleable cast iron

- HF – high-strength cast iron

- B – brass, bronze

- A – aluminum

- MN – monel metal

- P – plastic

- VN – vinyl plastic

- K – porcelain

- TN – titanium alloy

- SK – glass

This is followed by the numbers “YY” indicating the nomenclature general industrial series

- BC - without rings

- BR – brass, bronze

- MN – Monnel metal

- NJ – stainless steel

- NT – nitrided steel

- BT – babbitt

- ST – stellite

- SR – sormite

- K – skin

- E – ebonite

- R – rubber

- P – plastic

- VP – vinyl plastic

Example of decoding according to the classification of shut-off valves:

Let's look at one of the most popular examples. U 15s68nzh

15 – shut-off valve

C – carbon steel

68 – nomenclature designation

NZh – sealing material is made of stainless steel

The international standard for the classification of shut-off valves has clarified the general rules for the development, adoption, acceptance and application in the valve industry of countries that have approved this GOST.

Classification of shut-off valves

Classification of shut-off valves Devices installed on pipelines, called pipeline valves, are intended for a variety of purposes - control, regulation, protection,

What markings should shut-off valves have?

What markings should valves installed on pipelines have?

The fittings must be clearly marked on the body indicating:

a) name or trademark of the manufacturer;

b) conditional passage;

c) conditional or working pressure and temperature of the medium;

d) direction of medium flow;

Fittings with a nominal bore of 50 mm or more must be supplied with a passport of the established form, which indicates the materials used, heat treatment modes and the results of non-destructive testing, if these operations were provided for by the technical specifications. The data must refer to the main parts of the valve: body, cover, spindle, valve and fasteners.

The procedure for monitoring temperature movements of pipelines during operation.

On steam pipelines with an internal diameter of 150 mm or more and a steam temperature of 300 ° C or higher, displacement indicators must be installed to control the expansion of steam pipelines and monitor the correct operation of the support and suspension system. The installation locations of the indicators and the calculated values of movements along them must be indicated in the steam pipeline design. Directions must be freely accessible. Where necessary, platforms and stairs should be provided.

The value of test pressure during hydraulic testing of pipelines.

The minimum test pressure during hydraulic testing of pipelines, their blocks and individual elements should be 1.25 working pressure, but not less than 0.2 MPa (2 kgf/cm2).

What technical documentation should personnel servicing pipelines have at their workplace?

Operating personnel must be provided with production instructions developed on the basis of manufacturer's instructions for installation and operation, taking into account the layout of the equipment. Instructions are issued to service personnel against signature and are constantly located at the workplace. Technical documentation on the operation and repair of pipelines (passports, replacement and repair logs, pressure gauge check logs, etc.).

Price list for bends according to GOST 30753-2001 (ISO 3419-81)– SEAMLESS WELDED BENDS FROM CARBON AND LOW-ALLOY STEEL STEEP CURVED BENDS TYPE 2D (R ≈ DN)

Marking of shut-off valves

The accepted symbol (table of figures) consists of numbers and letters. The first two digits indicate the type/type of fittings (Table 1), the letters behind the numbers indicate the material of the basic parts - body, cover (Table 2), one or two digits after the letters indicate the registration number - if there are three digits, the first indicates the type of drive ( table 3), and the next two - registration number; the last two letters indicate the material of the sealing surfaces (Table 4). At the end of the designation, numbers are added that indicate the design option.

When ordering fittings, you must indicate:

name of the product and its brief description; type and design feature of the product (for example, a wedge valve with a sliding spindle); type of drive (manual, gear, electric, etc.); type of connection to the pipeline (flanged, welded); nominal or working pressure; drawing number, symbol; pipeline diameter; working environment indicating temperature; expected material of the base parts; the presence of a control environment, its type and parameters; additional technological requirements depending on the type of fittings (tightness, response cycle, resistance coefficient, etc. - if the consumer has information).

For example: 15s922nzh – steel gate valve, flanged through, with electric drive.

15 – according to table 1 – shut-off valve

c – sweat table2 – carbon steel

9 – according to table 3 – with electric drive

22 – model number

NZ – according to table 4 – sealing surfaces coated with corrosion-resistant steel.

Home News TPA Marking of shut-off valves

We draw your attention to the fact that our website is for informational purposes only and under no circumstances does the information materials and prices posted on the site constitute a public offer as defined by the provisions of Article 437 of the Civil Code of the Russian Federation. Availability, cost, completeness and delivery time must be previously agreed with the sales department of our company.

Great Encyclopedia of Oil Gas

Marking – fittings

The marking of the fittings in accordance with GOST 4666 - 65 must be applied to the body and contain: a) the manufacturer’s trademark; b) conditional pressure; c) nominal diameter, d) arrow showing the direction of flow. On fittings made of steel with special properties, the grade of the body material must additionally be indicated.

With an individual repair method, marking of fittings is carried out in accordance with RU-75. The fittings are issued to the process installation after completion of the repair.

What data is indicated in the marking of fittings.

The combustion test is usually completed by marking the reinforcement. For this purpose, special tags with indexes are installed under the mounting screws on the armature legs.

What data should be included when marking fittings.

Main characteristics of plastic inlet direct-flow valves of the Kosva type.

The symbol and marking of fittings allows you to select the correct type and material, the conditions for its use in pipelines and provide the ability to control when performing installation work.

After installation on the pipeline, the fittings are painted along with it. Symbols and markings of industrial fittings are given below.

Before installing the fittings, they are thoroughly inspected and all defects that appear as a result of storage or transportation are eliminated. In this case, it is necessary to check whether the marking data on the valves corresponds to the data in the manufacturer’s passport, to establish whether it meets the project requirements for nominal diameter, nominal, test and working pressures, as well as type. The marking is cast or stamped on the valve body, while the marking marks - conditional or working pressure, nominal diameter and medium flow direction arrow - are made on one side of the body, and the manufacturer's trademark is on the other. In the absence of a manufacturer's passport, fittings to be installed in gas supply systems must be disassembled and subjected to a full inspection and tested for strength and density in accordance with the requirements of GOST 356 - 59, as well as for air tightness depending on the operating pressure.

Conditional is the pressure at which a pipeline can operate if the temperature of the medium is 200 C. When the temperature of the medium increases above 200 C, the permissible operating pressure is reduced on a special scale to 45 - 36% (at 450 and 530 C) of the conditional pressure. Thus, marking of fittings according to conditional pressure requires verification according to the permissible operating pressure at a medium temperature above 200 C.

For pipelines made of stainless steel and aluminum, valves with a body and sealing parts (valve, seat) made of stainless steel are mainly used. The volume and types of preparatory work with reinforcement must be indicated in the projects and technical specifications. In general, all fittings accepted for installation are subject to an external inspection, during which the integrity of the original packaging, the condition of the body, spindle and sealing surfaces on the flanges are checked. The body must be free of cracks, cavities and other defects. The sealing surfaces must be free of scratches and signs of corrosion. The gland packing must be as required for the product. The spindle must be thoroughly polished and must move freely over the entire length of the thread. The painting and marking of the fittings must comply with the technical specifications.

What markings should shut-off valves have?

What markings should the fittings installed on pipelines have? The fittings must have clear markings on the body indicating: a) the name or trademark of the manufacturing enterprise...

According to GOST R 52720-2007 PIPELINE FITTINGS, table of figures (t/f) is a symbol, which is a combination of letters and numbers that determine the type and type of valve, the design of the valve, the material design of the body, the type and material of the seal in the valve, and the type of actuator."

It is very easy to understand the designations of tables and figures - just remember the tables of numbers of names of fittings and letters of materials. Letters are abbreviated names of materials.

Example

The table-figure consists of: - The first two digits - a table indicating the type of product (gate, valve, etc.). The complete list is given in Table 1.

Table 1

| The first two digits in the product type designation | Type of fittings |

|---|---|

| 10 | Trial crane |

| 11 | Pipeline tap |

| 12 | Locking device for level indicator |

| 13,14,15 | Stop valve |

| 16 | Check Valve |

| 17,28 | safety valve |

| 18,21 | Pressure regulator |

| 19 | Reverse shutter |

| 20 | Bypass valve |

| 22,24 | Waste valve |

| 23 | Distribution valve |

| 25,26 | Control valve |

| 27 | Mixing valve |

| 30,31 | Gate valve |

| 32 | Butterfly valve |

| 33 | Hose valve |

| 40 | Elevator |

| 45 | steam trap |

| 46 | Filter |

| 50 | Solenoid valve block |

The complete list is given in Table 2.

Table 3

If the drive is manual, then they usually indicate not three, but two numbers indicating the figure (model number). - after the numbers there are letters indicating the material of the sealing surfaces or internal coating (Table 4)

Table 4

To increase the service life, tightness and other characteristics of the product, surfacing from various materials is made on the inner surface of the body at the points of contact with the locking body. Their corresponding designations are given below:

If it is necessary to achieve certain parameters inside the entire product, an internal coating is applied. Then, instead of designating the material of the sealing surfaces, use the designation of the method of applying the internal coating:

Table 5

Examples of decoding using tables and figures:

1. 15kch888r:

- 15 - shut-off valve;

- kch - body made of malleable cast iron;

- 8 - control using an electromagnetic drive (if only 2 digits - manual control);

- 88 - model number;

- r - with rubber sealing rings.

2. 30nzh41nzh:

- 30 - valve;

- nzh - stainless steel body;

- 41 - model number (only 2 digits - manual drive);

- NZ - sealing rings are welded on stainless steel

At the end of the table of figures, a number may be inserted indicating various design options for the product, whether it is made of a different material, etc.

Examples

- 15nzh40p1- environments in relation to which the materials used are corrosion-resistant, the temperature of the working environment is up to 200 degrees.

- 15nzh40p2- working medium - freon containing oils, working medium temperature from minus 100 degrees Celsius to plus 150 degrees Celsius.

Previous page | |

|---|---|

According to " GOST 24856-2014. Pipeline fittings. Terms and Definitions" the name of the fittings must contain basic information about its type and (or) form, used in ordering, operational and design documentation. It may also include additional information ─ basic parameters, type of drive, information about belonging to various types.

Designation of fittings ─ this is the accepted designation of the main design document for valves in accordance with the Unified System of Design Documentation ESKD.

Pipeline accessories. Name in documentation

In Appendix B “GOST 24856-2014. Pipeline fittings. Terms and Definitions" provides recommendations on the formation of names of pipeline fittings used in technical documentation. It is no coincidence that they are given precisely in this regulatory document, the main task of which is to promote the standardization of terminology that “serves” pipeline fittings. The terms established therein should be used in the name of the fittings. If GOST 24856-2014 suddenly does not contain them, for example, characterizing any design features of reinforcement, it is permissible to use other words and phrases. The main thing is that they are as short as possible and clearly define the design features.

In order for the name of pipeline fittings to be as informative as possible, its type is placed first, followed immediately by its type. As you know, there are four types of fittings: gate valve, valve, faucet, butterfly valve. There are several more types of fittings:

● shut-off valves (however, in combination with the type of valve, the definitions “shut-off” and “shut-off” are not applied by default);

● return valves;

● safety fittings;

● distribution and mixing fittings;

● control valves;

● separating (phase separating) fittings;

● shut-off valves.

Plus several types of combined valves: shut-off-regulating, shut-off-check, non-return-shut-off, non-return-controlled.

Rice. 1. The procedure for forming the name of pipeline fittings in accordance with Appendix B of GOST 24856-2014.

A constructive variety is a synthetic concept that includes several components at once. Thus, depending on the design of the body, pipeline fittings can be straight-through, multi-pass, angled, etc. Depending on the method of rod sealing chosen - stuffing box, bellows, etc. There are a number of design features that deserve to be mentioned in the name of the fitting :

● control method ─ valves with hydraulic drive, pneumatic drive, electric drive, etc.;

● mode of action ─ cut-off, normally closed (NC), normally open (NO);

● design of the locking or regulating element;

● connection to the pipeline ─ flange, welding, coupling, pin, fitting;

● body material ─ steel, cast iron, aluminum, titanium, brass, bronze, etc.

GOST 24856-2014 lists the main parameters of pipeline fittings, which can be reflected in its name, as DN ─ nominal diameter, PN ─ nominal pressure, P p ─ working pressure, P ─ design pressure, t ─ design temperature.

DN is a parameter used as a characteristic of the connected parts of the fittings. Numerically, it corresponds to the internal Ø of the connected pipeline, expressed in millimeters.

PN corresponds to the highest excess pressure, expressed in kgf/cm2, at which (if the temperature of the working medium is 20 degrees Celsius) the specified service life of the valve body parts is ensured.

P p ─ the highest excess pressure at which a long-term normal course of the working process is possible at a given temperature and selected materials. Obviously, the higher the temperature, the lower the operating pressure.

P ─ excess pressure for which the strength of the reinforcement is calculated. Or in other words, the highest excess pressure at which its operation is allowed under normal operating conditions and design temperature.

t ─ temperature of the wall of the valve body under normal operating conditions. Equal to the highest arithmetic mean of the temperatures of the outer and inner surfaces in one section.

GOST 24856-2014 allows pipeline fittings to be given abbreviated names that do not contain references to DN, PN, P p and t. Both very short, for example, a ball valve, a gate valve, and more extensive ones ─ a ball valve with a pneumatic drive, a gate valve with a hydraulic drive, a flanged cone valve, a cast iron flanged cone valve, etc.

Pipeline fittings in the All-Russian Classifier of Products and Design Documents OK 012-93

The All-Russian Classifier of Products and Design Documents (ESKD Classifier) OK 012-93 was put into effect on July 1, 1994. The structure of the code designation in it is as follows:

Rice. 2. Structure of the classification characteristic code designation in the All-Russian Classifier of Products and Design Documents OK 012-93

Class 490000 “Pipeline fittings” includes five subclasses:

● 490000 ─ “Documents (norms, rules, methods)”;

● 491000 “Shut-off and non-return shut-off valves without built-in drive devices”;

● 492000 “Shut-off and non-return shut-off valves with built-in drive devices”;

● 493000 “Control and mixing valves”;

● 494000 “Safety valves, check valves, multi-way valves, distribution valves, phase distribution valves, indicating valves and others;

● 495000 “Equipment components”.

Each subclass is divided into several groups. For example, subclass 492000 “Shut-off and non-return shut-off valves with built-in drive devices” includes several groups:

492100 “Valves (valves), kingstons, check valve boxes through passage”;

492200 “Valves (valves), kingstons, corner valve boxes”;

492400 “Disk and hose shut-off valves (latches, flaps)”;

492500 “Parallel and gate valves”, etc.

Example of subgroups:

492130 “Valves (valves), kingstons, valve boxes, check valves, stuffing box, with a diameter over 200 mm”;

492160 “Valves (valves), kingstons, bellows-type shut-off valve boxes with a diameter over 200 mm”;

492180 “Valves (valves), kingstons, valve boxes, check-off passage membrane combined and others with a diameter from 50 to 200 mm inclusive”;

492190 “Valves (valves), seacocks, valve boxes, check valves, passage membrane combined and others with a diameter of over 200 mm.”

And finally, a few examples of types:

492131 “Valves (valves), kingstons, valve boxes, check-off stuffing box, with a diameter over 200 mm with a threaded or pin-type connection to the pipeline”

492134 “Valves (valves), seacocks, check valve boxes, stuffing box, with a diameter of over 200 mm with a welded connection to the pipeline.”

Pipeline fittings in the All-Russian Classifier of Products OKP (OK 005-93) and the All-Russian Classifier of Products by Type of Economic Activity OK 034-2014 (KPES 2008)

ESKD is not the only classifier that contains formalized information about pipeline fittings. The All-Russian Classifier of Products OKP (OK 005-93), which is part of the Unified System of Classification and Coding of Technical Products, has still not lost its relevance. economic and social information (ESKK) of the Russian Federation. But from January 1, 2017, it loses force, due to the publication of Rosstandart Order No. 14-Art dated January 31, 2014. It will be replaced by the All-Russian Classifier of Products by Type of Economic Activity OK 034-2014 (CPES 2008), adopted by the same order.

Why are such classifiers needed? They help in solving a number of problems related to industrial and agricultural products:

● its cataloging and systematization in catalogs according to the most important technical and economic characteristics;

● certification;

● statistical analysis of production at different levels ─ macroeconomic, regional, sectoral;

● structuring industrial and economic information for marketing research.

In the OKP classifier (OK 005-93), which represents a systematic set of codes and names of product groupings built according to a hierarchical classification system, industrial pipeline fittings are assigned class 37 0000. Each position contains a six-digit code, for pipeline fittings always starting with the numbers 37 (in the head of the table ─ “Code”), control number (“CN”) and the name of the group (“Name”).

For example, 370000 6 “Industrial pipeline fittings”,

the third digit indicates the material of the fittings or its affiliation with auxiliary devices:

37 1000 9 Industrial pipeline fittings made of non-ferrous metals and alloys;

37 2000 1 Industrial pipeline fittings made of gray cast iron;

37 3000 4 Industrial pipeline fittings made of ductile cast iron;

37 4000 7 Industrial pipeline steel fittings;

37 6000 2 Industrial pipeline fittings made of non-metallic materials;

37 9000 0 Auxiliary devices.

How adding the following numbers after these first three helps to detail the idea of reinforcement can be judged by the following examples:

37 2100 5 Gate valves and valves made of gray cast iron;

37 2110 5 Gate valves and valves made of gray cast iron with DN up to 150;

37 2111 5 Wedge valves made of gray cast iron with DN up to 150 with a rising spindle;

37 2112 0 Wedge valves made of gray cast iron with DN up to 150 with a non-rising spindle;

37 2113 6 Double-disc wedge valves made of gray cast iron with DN up to 150 with a rising spindle;

37 2114 1 Double-disc wedge valves made of gray cast iron with DN up to 150 with a non-rising spindle;

37 2115 7 Double-disc parallel gate valves made of gray cast iron with DN up to 150 with a rising spindle.

The new classifier OK 034-2014 (KPES 2008) uses a hierarchical classification method and a sequential coding method. The code contains from two to nine digital characters.

Pipeline fittings are assigned code 28.14. Where 28 (this class) means “Machinery and equipment”, 28.1 (subclass) ─ “General purpose machines and equipment”, and 28.14 (group) ─ “Taps, valves, etc.” (that’s what pipeline fittings are called in this document). Examples of subgroups: 28.14.1 ─ “Taps, taps, valves and similar fittings for pipelines, boilers, tanks, tanks and similar containers” or 28.14.2 ─ “Parts of taps, valves and similar fittings”.

The combination of six numbers means the type ─ 14.28.11 ─ “Reducing, control, check and safety valves.” Or 14.28.20 ─ “Components (spare parts) for taps and valves, and similar fittings that do not have independent groups.”

As experts note, and which is easy to verify by independently reading the relevant regulatory documents, there is no complete continuity between the All-Russian Classifier of Products OKP (OK 005-93) and the All-Russian Classifier of Products by Type of Economic Activity OK 034-2014 (KPES 2008). The new classifier does not include some types and types of pipeline fittings, which are presented in OK 005. Not all terms in it correspond to those adopted in GOST 24856-2014 “Pipeline fittings. Terms and Definitions".

The combinations of numbers in the last of the considered classifiers are very similar to the numbers contained in the output data of printed publications ─ the universal decimal classification (UDC) and library-bibliographic classification (BBC) indices used in book publishing and library science.

If the book deals with pipeline fittings, you can see the UDC index 621.646. The combination of the first two digits 62 indicates that the subject of the publication belongs to engineering and technology in general. The combination of numbers 621.646 ─ specifically for pipeline fittings.

A more detailed interpretation is possible: adding a one at the end of 621.646.1 informs that the book talks about general issues related to shut-off devices (shut-off valves), and adding a six 621.646.6 ─ about valves in pipeline fittings. Moreover, this six can be deciphered. 621.646.61 ─ types of crane construction; 621.646.62 ─ taps, subdivided according to the method of connection to the pipe; 621.646.63 ─ multi-way valves; 621.646.65 ─ taps, divided by purpose, etc.

The library-bibliographic classification index helps to quickly determine in which “box” (including electronic) of systematic catalogs and card files of library collections information about a book should be placed. Books on pipeline fittings can be assigned the BBK index 39.7 (Pipeline transport) or 39.71 (Main pipelines, main pipeline transport), 39.76 (Gas pipelines), 39.78 (Technological pipelines). And some others.

The topic of names, designations and coding systems in pipeline fittings is very extensive and deserves more careful consideration than the scope of one article allows. This is especially true for such an aspect as Tables of figures and symbols, which underwent changes in 2014-2015. quite significant changes.